Join us on a visit to the "Cloud Factory," a small factory in Tuscany, nestled in the lush Val di Nievole. Here, the production of exclusive down products has continued since the 1960s, and everything is still owned by the same family. This factory is one of the few in Europe that still manages and maintains full oversight of the entire down product manufacturing chain.

This fluffy story began in 1964 with founder Silvano Cinelli’s deep passion for down—a drive that led to the creation of technical down garments for the first Italian expedition to Antarctica. So, if you're someone who feels the cold, rest assured—we know how to keep you warm.

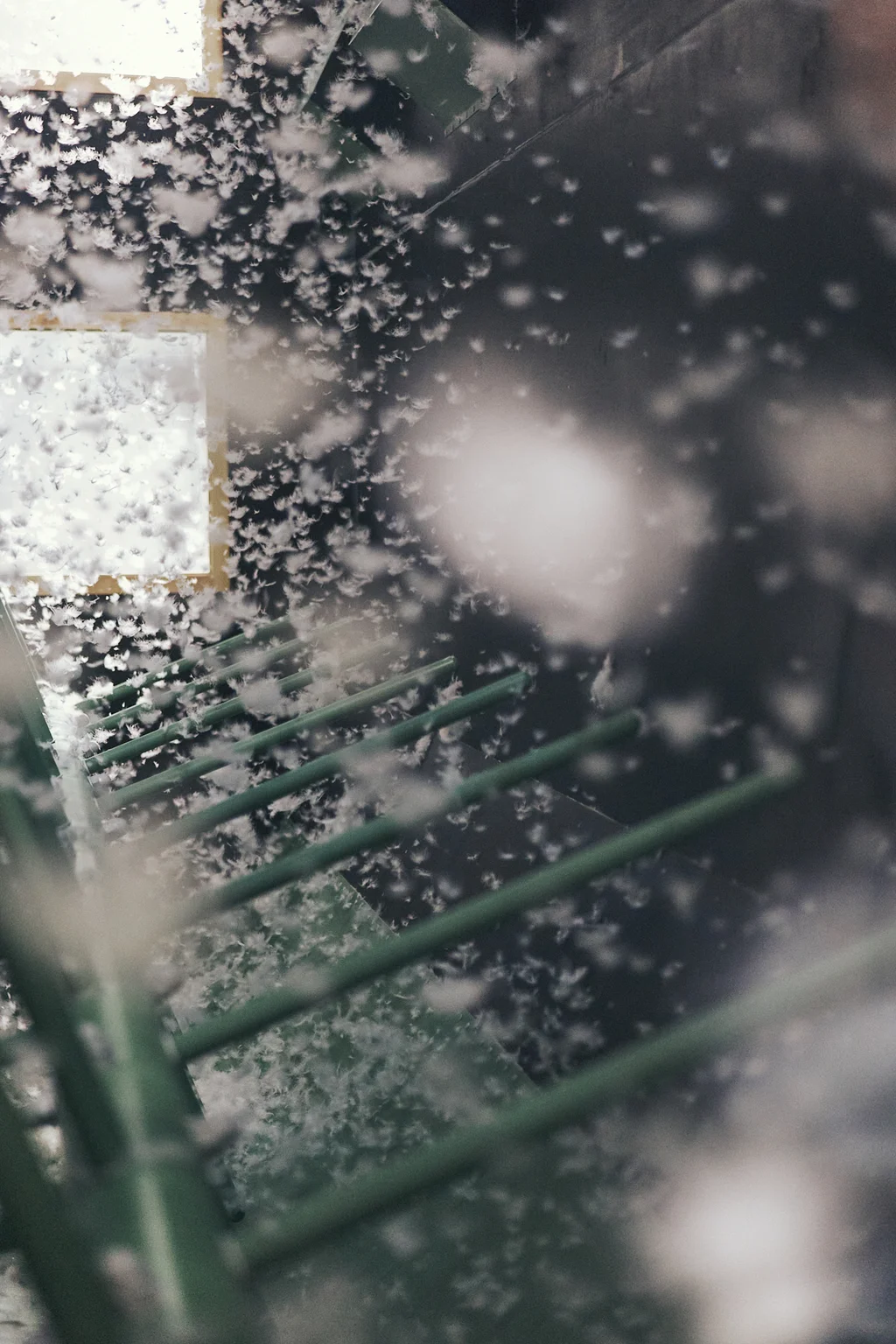

Now that we’re here in Tuscany, let’s take a tour!

When we visit our factory, it's fun to talk to the seamstresses. Here, all exclusive down products are handmade. They sew all sorts of things. From channel-stitched exclusive down vests where each channel is filled with a different amount of down (thus exactly different in grams!) "More filling over shoulders and neck for warmth, and less around the waist for the silhouette!" ...to sofa cushions for boats and hotels. They think our down duvets are totally bananas but fun.

They fill the bolsters with a kind of reverse down vacuum cleaner. Initially, the packaging itself was a problem: packing the finished duvet in its fabric packaging was heavy and time-consuming. So we changed the dimensions of the fabric bag and our shipping boxes. The result is what you see today: perfect to the millimeter. Easy to pack but not overly bulky on the shelf. It's easy to find solutions when each step is clear.

Our fluffy duvets are then filled (to height!) using a machine that could be described as a reverse down vacuum cleaner.

Achieving the perfect fluffiness level was a significant challenge during the creation of Happy Fluffy Cloud and is now a process with absolute millimeter precision, where each bolster is filled with an ultimate mix and amount of feathers and down.

The feathers contribute to height and resilience, while the down creates warmth and softness. Our two duvet models are constructed in different ways:

A down bolster with a channel-stitched frame on the outer edge. The seams are sewn after the down and feathers are evenly distributed. The midifluff also contains less filling, making it cooler.

A large down bolster that lacks channel stitching, yet the down stays in place thanks to the right amount (plenty) of filling. The idea here is that you can distribute the down to where you want more warmth.

Welcome to the laboratory, a factory within the factory. Here, the raw materials are tested to ensure quality through so-called spot tests. This process is done by hand to verify the quality of the raw materials.

The down is separated from the feathers. A feather consists of 360g of feather and 40g of down. The feathers are heavier than the down, which means the finest down remains in the air chamber after the filtration process.

The raw material undergoes an initial cleaning to remove dust residues. It is then washed an additional 7 times with water and soap—three times in warm and four times in cooler water (50-60 degrees).

Next, it’s time for drying, which takes place in a 130-degree silo. During this process, it is also sterilized. Finally, there is a so-called dust removal step to eliminate any remaining dust after sterilization.

Our bolsters consist of a blend of feathers and down from selected European breeders who do not practice feather plucking, which causes unnecessary suffering to the animals. The geese are raised outdoors for the purpose of being used as food and enjoy a good quality of life. Read more about Sustainability.